Production management

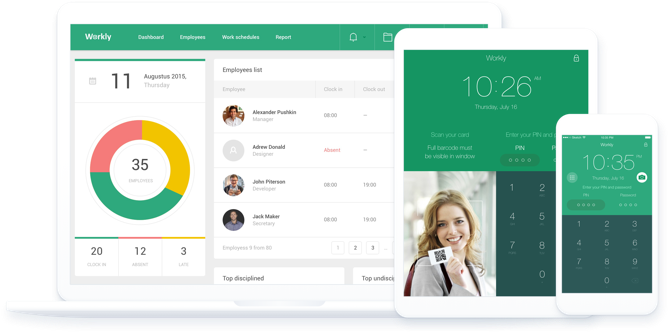

- Workly

- Business Solutions

- Production

Compliance with working standards and other modern problems of production

Efficiency of modern manufacturing enterprises is directly related to the effectiveness HR management. Here are just some of the urgent problems:

- Unreasonable equipment downtime due to staff absences and late arrivals and shortage of labor resources in the shift.

- Equipment revamping due to violations by maintenance staff and improper work shift scheduling.

- Complicated analysis of each work shift and further optimization of the work schedule.

Actual accounting, timekeeping accounting and attendance monitoring, analytics, and personnel planning at the place of production

Workly improves staff interaction at production facilities and automates routine tasks.

- Records the staff clock-in and clock-out times.

- Data exchange with ERP systems (1C/SAP), which simplifies time keeping

- Automatically generates reports for each employee.

- Analyzes the history of employees and recommends the best work schedule.

- Reduces Salary Fund (budget) by tracking non-attendance, absences, and early terminations.

Automate your workforce management processes

Working time management

Monitor violations of the work schedules in real time.

Working schedule

Optimal staff composition to meet production needs.

Payroll calculations

Automatic tabling helps to avoid payroll errors and saves time.

Workly can exchange data with other systems at the place of production

Improve the level of information and asset protection.

- Set access levels to different premises.

- Connect biometrics to recognize employees by a photo from a tablet camera connected to Workly TimePad, or from peripheral equipment.

- Integration with Remote Access Control Systems (RACS).

- Automatic notifications when attempting to enter a production facility without authorization.